Titanium sheets and plates can indeed be recycled, contributing to both environmental sustainability and economic efficiency. Recycling titanium plates and sheets reduces the need for extracting new titanium ore, conserving valuable natural resources and minimizing the environmental impact associated with mining and processing. Additionally, recycling consumes less energy compared to the production of virgin titanium, leading to energy savings and reduced greenhouse gas emissions. It also helps manage and reduce the disposal of titanium scrap and waste materials, promoting responsible resource management. As a cost-effective and eco-friendly practice, titanium plates and sheets recycling aligns with the principles of sustainability and responsible resource utilization.

Titanium Heat Exchanger

Esterification Tower

Titanium Sterilization Tank

Falling-film Evaporator

Titanium Venturi

Titanium Piping

Titanium Pipe Fittings

Titanium Fasteners

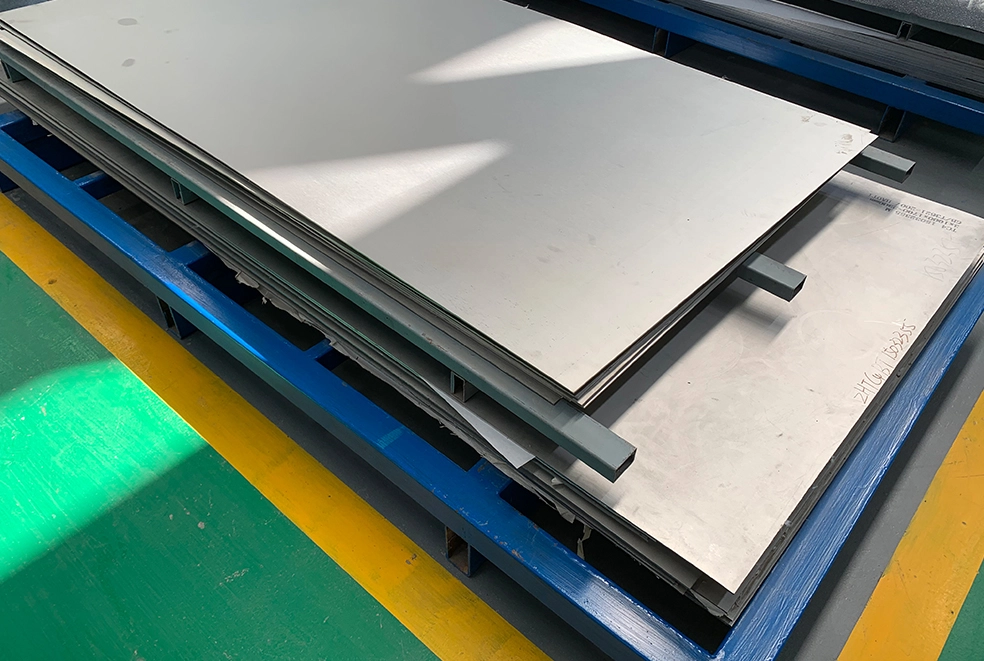

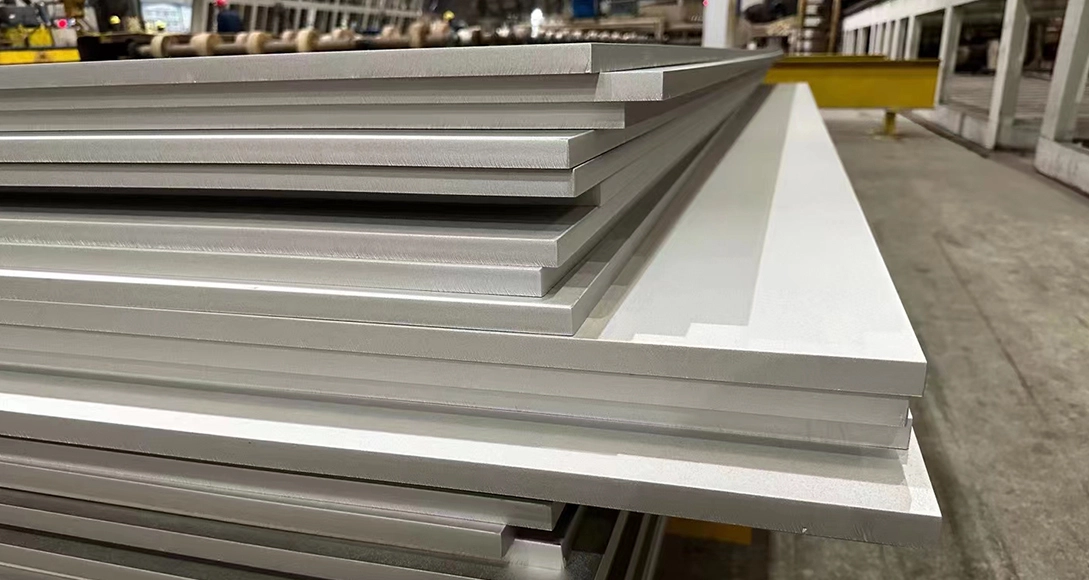

Titanium Plate

Titanium Sheet

Titanium Tube Sheet

Titanium Foil

Titanium Strip

Titanium Clad Steel Plate

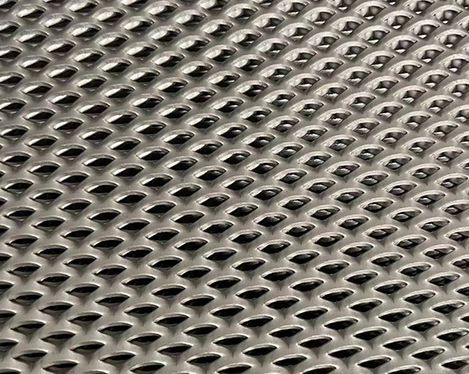

Porous Titanium Sheet

Titanium Mesh Sheet

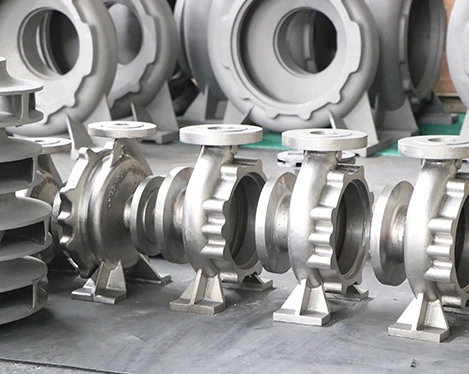

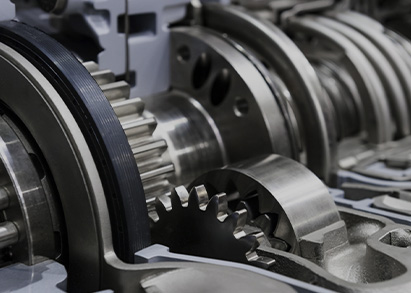

Titanium Casting

Seamless Titanium Tube

Welded Titanium Tubing

Gr5 Titanium Tube

Titanium Capillary Tube

Titanium Retangular/Square Tube

Titanium Coil Tube

Titanium Sputtering Target

Sintered Titanium Tube

Nitinol Tube

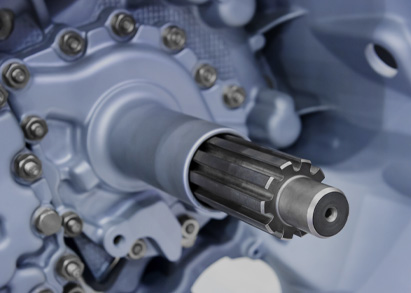

Titanium Rod

Titanium Block

Titanium Square/Hex Rod

Titanium Hollow Bar

Titanium Threaded Rod/Bar

Titanium Welding Wire

Titanium Wire

Titanium Clad Copper Rod

Nitiol Wire

Ruthenium Coated Titanium Anodes

Iridium Coated Titanium Anode

Platinized Titanium Electrodes

PbO2 Titanium Anode

Titanium Basket

Titanium Cathode Plate

×

English

English