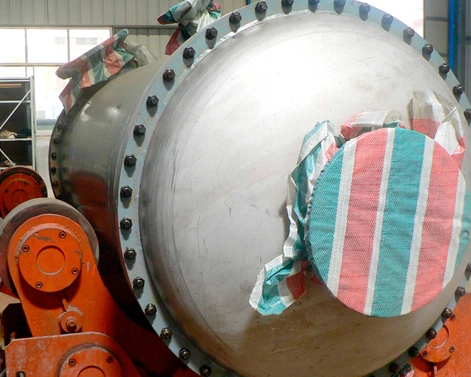

Pressure Vessel Class | Grade1 |

Designing pressure | 0.1Mpa for tube, 0.88Mpa for shell |

Pressure-tight test | 0.13Mpa for tube, 1.22Mpa for shell |

Designing temperature | 100℃ for tube, 185℃ for shell |

Max working pressure | 0.03Mpa for tube, 0.8Mpa for shell. |

Heat exchange area | 140m² |

Media | EAC for tube, steam for shell |

Tube material | S30408 |

Shell material | carbon steel |

Weight | 4814kg |

Application | This equipment is used for material heating in fine chemical plants in Canada, wall-type heat exchange, and belongs to the first-grade pressure vessel. |

The reboiler, as the name suggests, make the liquid vaporize again. Its structure is similar to the condenser, but one is used to cool down, and the re-boiling device is used to heat and vaporize.

The reboiler is mostly combined with the fractional tower: The re-boiler is a special heat exchanger that can exchange calories and has a vaporization space. The material liquid level and the fractional tower liquid level in the reboiler are at the same height. Provide liquid phase from the bottom line to enter the re-boiling device. Usually 25-30%of the liquid phase is vaporized in the re-boolizer. The two-phase flow of vaporization was returned to the fractional tower, and the gas group returned to the tower was divided into upward through the tower plate, and the liquid phase group was divided into the bottom of the tower.

The material is heating or even vaporization in the reboiler device, and the density becomes smaller, so as to leave the vaporization space, return to the tower smoothly, return to the two phases of the gas liquid in the tower, the gas phase is upward through the tower plate, and the liquid phase will fall to the bottom of the tower. Due to the effects of static pressure, the bottom of the tower will continue to supplement the part of the liquid level that has been evaporated.