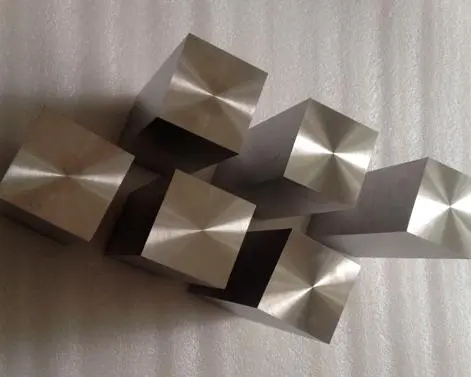

Material | gr1 gr2 gr3 gr4 gr5 gr7 gr9 gr12 gr23 TC1 TC11 TB9 TB5 |

Size | (80-300) * (200-1200) * (200-1500) mm |

Standards | ASTM B381, ASTM F67, ASTM F136, AMS 4928 |

Production process | Forged |

Delivery status | M annealed, STA solution aged treatment |

Surface | machining |

Aerospace | Jet engine components, fuselage components, rockets, artificial satellites, missiles and other components, compressor and fan blades, disks, casings, guide vanes, shafts, landing gears, engine compartments, fuel tanks, boosters. |

Chemistry, Petrochemical and General Industry | Used for industrial components such as chlor alkali, soda ash, petrochemical, metallurgical salt production, etc. |

Ships | Submarine pressure hull, propeller, ship pump, etc |

Ocean Engineering | Seawater desalination, pumps, valves, etc. for offshore oil drilling |

Biomedical | Artificial joints, surgical instruments, pacemakers, etc |

Automobile | Load bearing springs, connecting rods, bolts, etc |

Quality: At Changsheng Titanium, we prioritize quality above all else. Our Titanium Blocks are manufactured to the highest standards, ensuring they meet the rigorous demands of various industries.

Expertise: With years of experience in the field, we have developed unparalleled expertise in producing Titanium Blocks. Our team of experts is always ready to provide advice and support, ensuring you get the most suitable product for your needs.

Flexibility: We understand that every customer has unique needs. That’s why we offer flexible solutions, including customized Titanium Blocks tailored to your specific requirements.

Short Lead Time: We pride ourselves on our efficient production processes, which allow us to offer short lead times without compromising on quality.

Large Stock: We maintain a large stock of Titanium Blocks, ensuring we can quickly fulfill your orders, no matter how large or small.

Competitive Prices: Despite the superior quality of our Titanium Blocks, we offer them at competitive prices. This ensures you get the best value for your money.

Weight Reduction: Titanium boasts a significantly lower weight compared to traditional cast iron engine blocks. This translates to lighter vehicles, improved fuel efficiency, and increased range – a major perk for electric vehicles aiming to maximize driving distance on a single charge.

High Strength-to-Weight Ratio: Despite being lightweight, titanium engine block offers exceptional strength and durability. This allows for thinner engine block walls without sacrificing performance. Imagine a lighter engine block that maintains robust construction – a win for both performance and fuel efficiency.

Corrosion Resistance: Titanium engine block is highly resistant to corrosion, even under harsh operating conditions like extreme temperatures and exposure to road salts. This translates to a longer engine lifespan and reduced risk of breakdowns caused by engine block corrosion.

Improved Heat Dissipation: Titanium engine block conducts heat better than cast iron, allowing for more efficient engine cooling. This helps prevent overheating and engine damage, particularly beneficial for performance applications that push the engine’s limits.

Potential for Performance Applications: The unique properties of titanium engine block make it ideal for high-performance vehicles where shaving off weight and achieving optimal engine performance are critical. Think high-end sports cars or motorcycles where every pound counts.