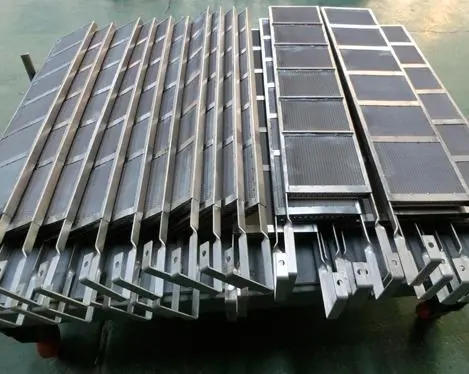

Platinized Titanium Electrodes Specification

| Processing | electroplating |

| Substrate | titanium Gr1/Gr2 |

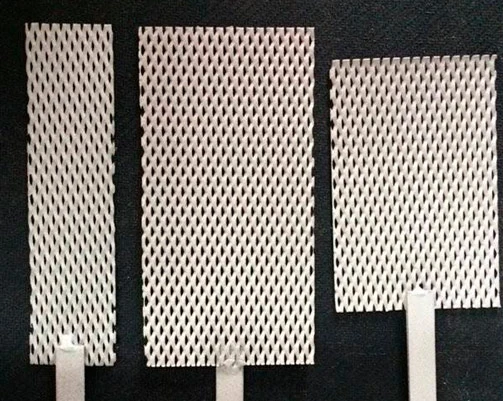

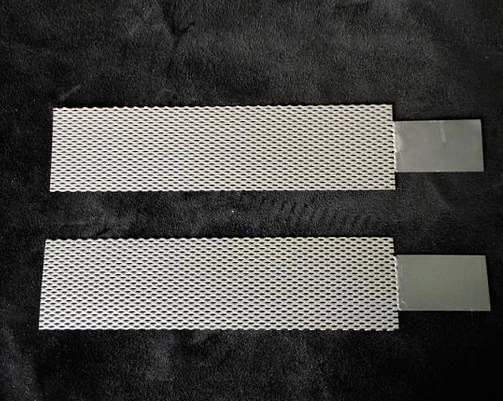

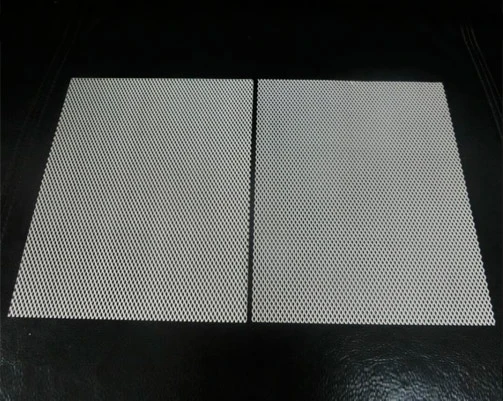

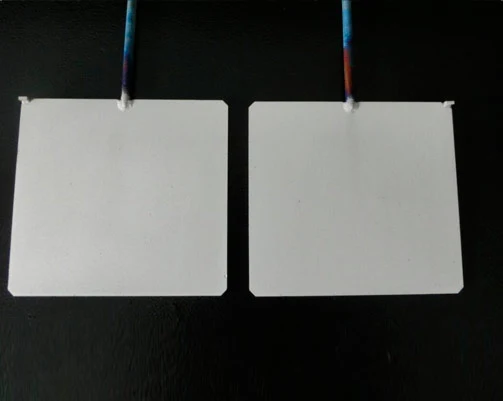

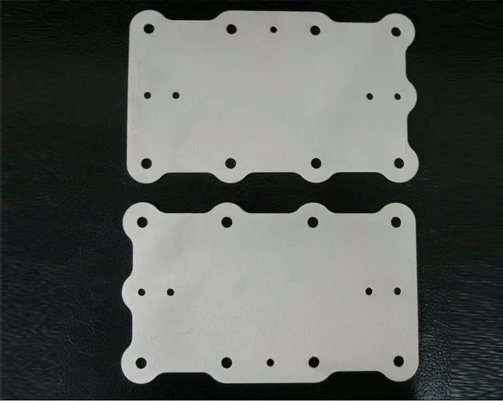

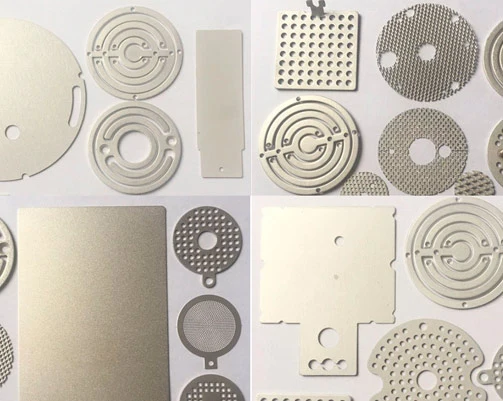

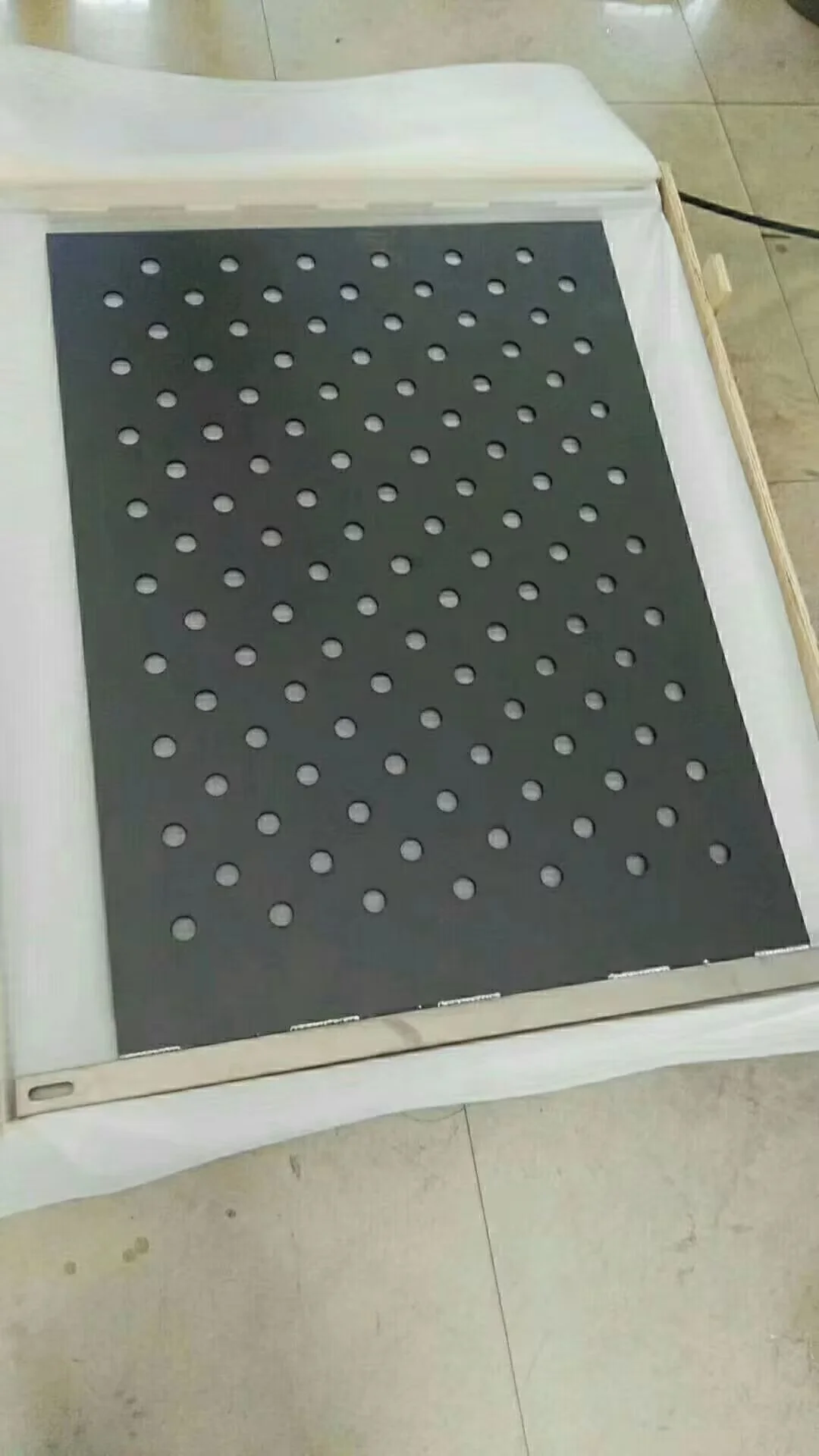

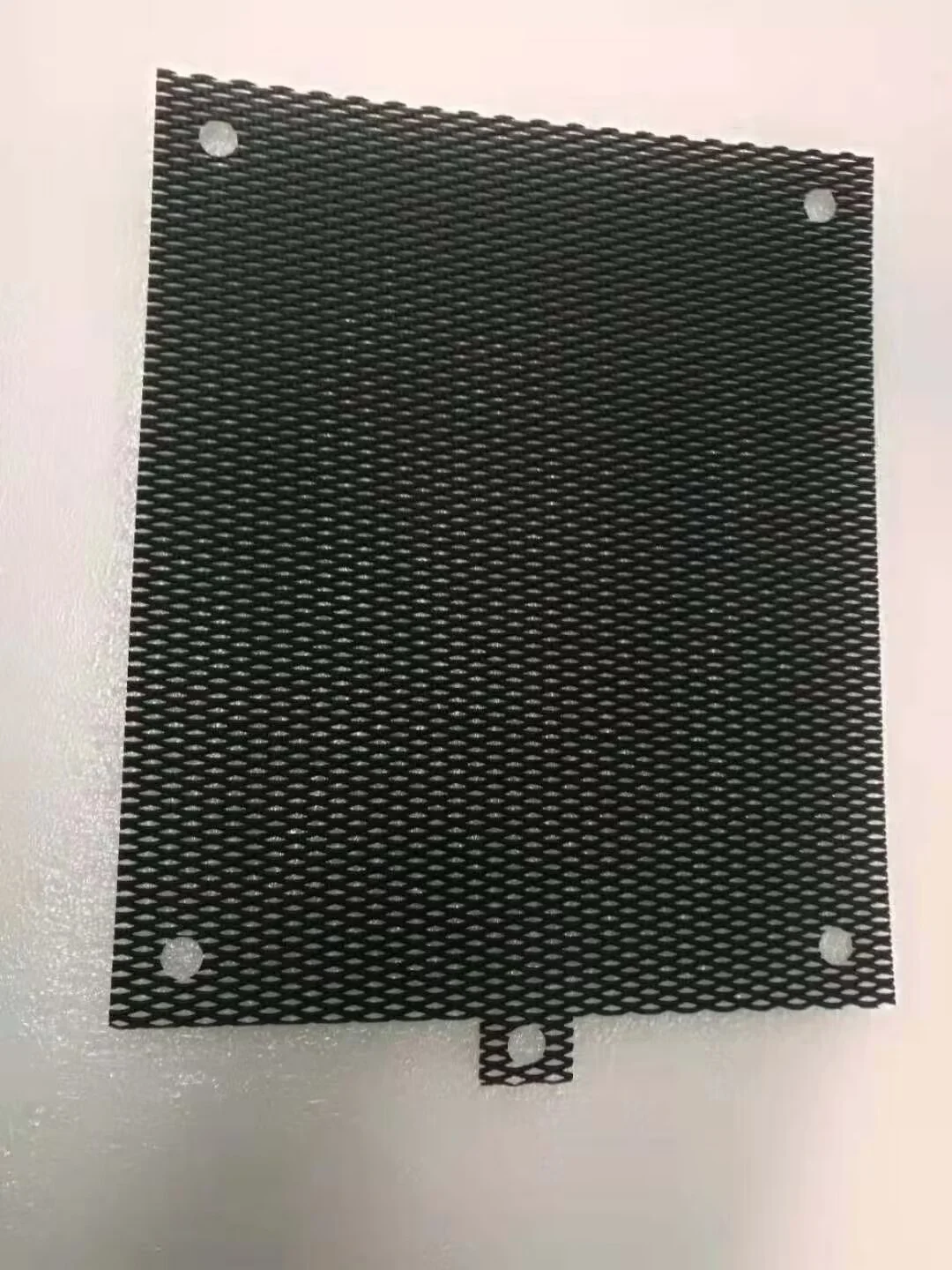

| Shape | Plate | Mesh | Tube | Wire |

| Thickness: 0.8-5mm | Thickness:1-3.5mm | OD: 25/32/45/60.5mm | Dia: 1/2/3mm |

| Hole: 3*6mm;4.5*12.5mm | Thickness: 1/1.2/1.5mm |

|

| Coating materials | platinium |

| Coating thickness | 0.5-10um |

| Operating current | ≤7500A/m2 |

| Operating voltage | ≤24V |

| Fluorides-content | ≤50mg/L |

| PH-range | 1-12 |

Platinized Titanium Electrodes Features

Dimensionally stable;

Constant cell voltage;

Highly conductive;

Good corrosion resistant properties in sulphate solutions;

Reduced electricity consumption;

Lower oxygen overvoltage;

Lighter weight, ease installation and removal;

Shorter downtimes;

No sludge is formed as the anodes don’t dissolve like lead;

Longer bath life;

Easily fabricated into any shape.

Platinized Titanium Electrodes Applications

Cathodic Protection with high current densities, for example Sea water intakes, Heat exchanger & Condensers, Jetties & Tanks, Water Heaters

Electroplating Industries such as Precious metal plating, Gold plating, Electrolytic Cells, Rhodium Plating, Sensing Elements, Electro galvanizing, Electro chlorination, Hard Chrome Plating, Waste water treatment, Precious Metal Recovery, Rotogravure printing

Platinized Titanium Electrodes Advantages

Platinized titanium anodes are widely used in both chlorine and oxygen evolution electrodes. In recent years, drinking water disinfection and sterilization and HHO are the areas with large purchase volume. In the field of drinking water disinfection and sterilization, ruthenium-iridium titanium anode can also play the role of platinum coated titanium anode electrolysis, but ruthenium itself has a certain toxicity. In microscopic terms, the consumption of electrodes and the shedding in use will cause trace elements to dissolve in water. Therefore, platinized titanium anode is often used in the field of disinfection and sterilization related to the treatment of drinking water.

In the field of HHO production, platinized titanium anodes are mainly used for electrolytic hydrogen production. Platinum coated titanium anode is commonly used in the field of HHO (hydrogen oxygen mixed gas) generation for hydrogen production by electrolysis. HHO generation is a process of decomposing Water splitting into hydrogen and oxygen, and hydrogen and oxygen are generated by Electrolysed water. In this process, suitable electrolytes and electrode materials need to be used. Platinized titanium anode is chosen as the anode material in the electrolysis process of hydrogen production because it has high corrosion resistance and catalytic performance, can provide a stable electrochemical reaction interface during the electrolysis process, and promote the electrolysis of water molecules. It also has good conductivity and durability, and can maintain good performance during long-term electrolysis processes.

Custom Platinized Titanium Anode

Changsheng Titanium Electrode Supplier specializes in providing high-quality custom platinized titanium anodes, catering to a wide range of industrial applications where durability and efficiency are paramount. Our platinum coated titanium electrodes are designed to meet the specific needs of our clients, ensuring optimal performance in various electrochemical processes.

The platinized titanium electrode, a flagship product of Changsheng Titanium Electrode Supplier, stands out for its exceptional electrocatalytic properties. By applying a thin layer of platinum onto the robust titanium substrate, we create an anode that combines the excellent conductivity and corrosion resistance of platinum with the strength and durability of titanium. This synergy results in a platinized titanium anode that offers superior performance, longevity, and cost-effectiveness.

Our platinised titanium anodes are utilized in a multitude of applications, including water treatment, cathodic protection, electroplating, and the chlor-alkali industry. The unique properties of the platinum coating ensure a high degree of efficiency and reliability, making our electrodes the preferred choice for clients seeking to optimize their electrochemical processes.

At Changsheng Titanium Electrode Supplier, we are committed to innovation and quality. Our custom platinized titanium anodes are tailored to meet the precise requirements of each application, ensuring that our clients receive the most effective and sustainable electrochemical solutions. With our expertise and dedication, we continue to set the standard for excellence in the field of titanium electrodes.

English

English