With the continuous progress and development of aerospace technology, titanium alloy materials have become a very important type of material. Titanium alloy materials have the advantages of light weight, high strength, high corrosion resistance, and high temperature stability, which greatly improve the performance of aircraft, satellites, and rockets. Here are some of the key applications and features of titanium for the aerospace industry:

Airframes: Titanium and titanium alloys are used in the construction of airframes and structural components of aircraft. Titanium's high strength-to-weight ratio allows for lightweight yet durable airframe structures, contributing to improved fuel efficiency and performance.

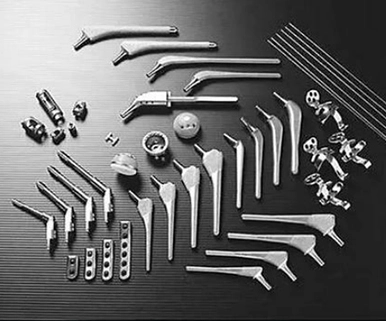

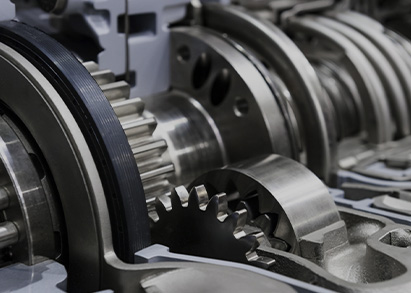

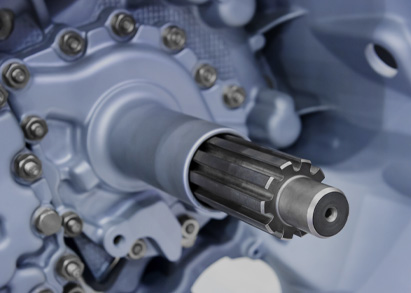

Engine Components: Titanium is widely used in aircraft engines due to its high temperature resistance, corrosion resistance, and strength. The titanium aircraft parts is used in components such as compressor blades, turbine blades, casings, and disks. These titanium aerospace parts operate under extreme conditions and require materials with excellent mechanical properties.

Landing Gear Systems: Titanium's strength, toughness, and corrosion resistance make it well-suited for landing gear systems. Landing gear components, including struts, beams, and fasteners, benefit from titanium's lightweight nature, as it helps reduce the overall weight of the aircraft while maintaining structural integrity.

Fasteners: Titanium fasteners, such as bolts, nuts, and screws, are used extensively in aerospace applications. They offer high strength, corrosion resistance, and are lightweight, making them ideal for securing critical components while minimizing weight.

Exhaust Systems: Titanium industrial uses in exhaust systems of aircraft engines due to its ability to withstand high temperatures and corrosion resistance. It helps in the efficient discharge of exhaust gases while maintaining structural integrity in demanding operating conditions.

Hydraulic Systems: Titanium is utilized in hydraulic systems within aircraft for various components such as valves, fittings, and tubing. Its corrosion resistance is particularly beneficial in systems that come into contact with hydraulic fluids.

Satellite and Spacecraft Components: Titanium is employed in the construction of satellites and spacecraft due to its lightweight properties, corrosion resistance, and strength. It is used for structural elements, heat shields, fuel tanks, and other critical components.

Aircraft Interiors: Titanium and titanium alloys are used in the interior design of aircraft for applications such as seat frames, tray tables, and other lightweight yet strong components.

Titanium is not only used in aerospace, aircraft,and spacecraft, but also used in military, medical and chemical field. For more information about titanium alloys applications, please connect with CS Titanium supplier.

Advantages of Titanium Used In Aerospace and Aircraft

Weight Savings: Titanium’s high strength-to-weight ratio makes it an ideal material for aerospace and aircraft applications, where weight savings are crucial for fuel efficiency and performance.

Space Limitations: Titanium’s strength and durability allow for the creation of thinner, lighter components, effectively addressing space limitations in aircraft design.

Composites Compatibility: Titanium’s compatibility with composites allows for the creation of hybrid structures, combining the best properties of both materials for superior performance.

Low Modulus: The low modulus of titanium contributes to its flexibility and resilience, making it ideal for the dynamic stresses experienced in aerospace applications.

Good Specific Strength: Titanium’s specific strength is higher than that of many other metals, making it a reliable choice for structural components in aircraft.

Elevated Temperature Capabilities: Titanium can withstand high temperatures, making it suitable for parts close to engines or other heat-generating components.

Cryogenic Temperature Capabilities: Titanium’s performance remains stable even at cryogenic temperatures, making it ideal for space applications.

Titanium is used in other industries that you are sensitive to

English

English