The choice of form depends on factors such as the specific electrochemical reaction, the required surface area, the geometry of the electrolyte cell, and the desired efficiency. Additionally, coatings of noble metals like platinum, ruthenium, or iridium oxide are often applied to these titanium forms to enhance their electrocatalytic properties and improve their performance in various electrochemical processes.

Titanium Heat Exchanger

Esterification Tower

Titanium Sterilization Tank

Falling-film Evaporator

Titanium Venturi

Titanium Piping

Titanium Pipe Fittings

Titanium Fasteners

Titanium Plate

Titanium Sheet

Titanium Tube Sheet

Titanium Foil

Titanium Strip

Titanium Clad Steel Plate

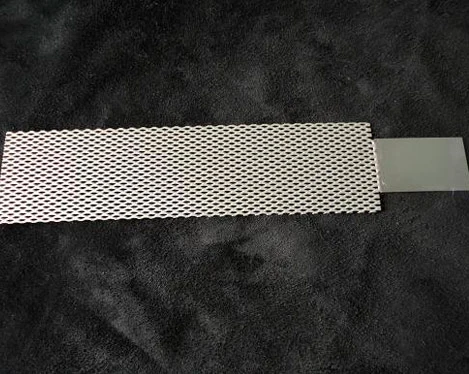

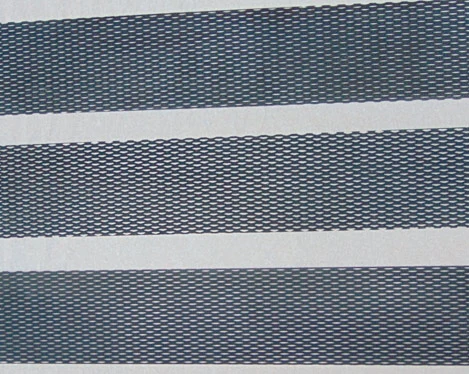

Porous Titanium Sheet

Titanium Mesh Sheet

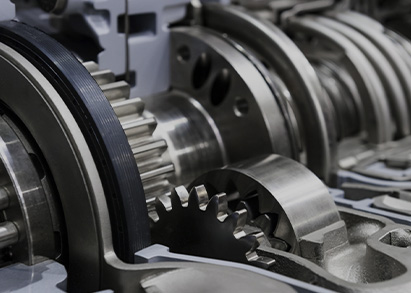

Titanium Casting

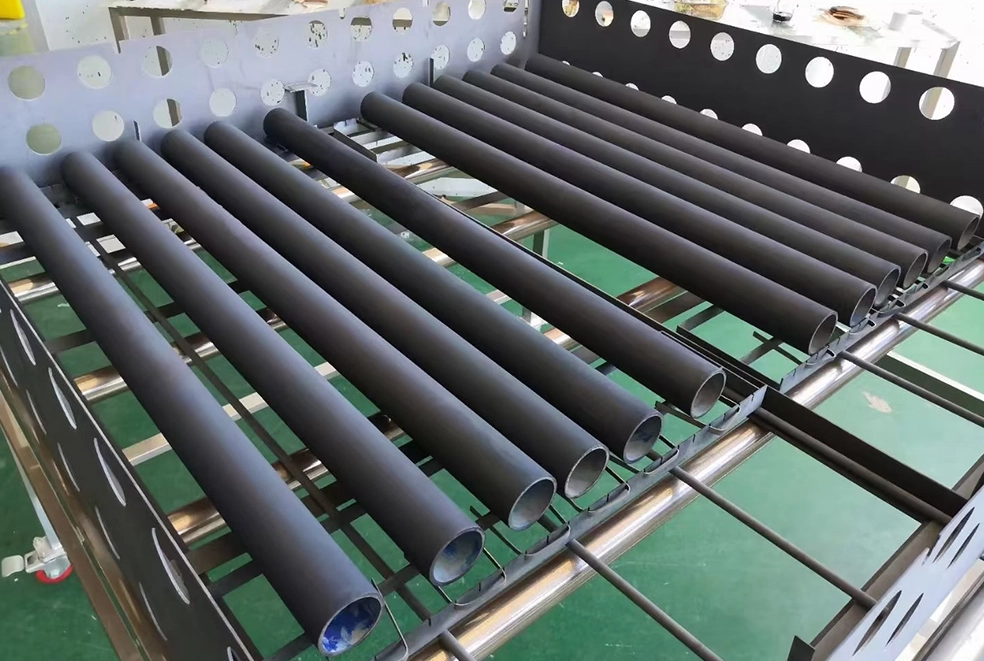

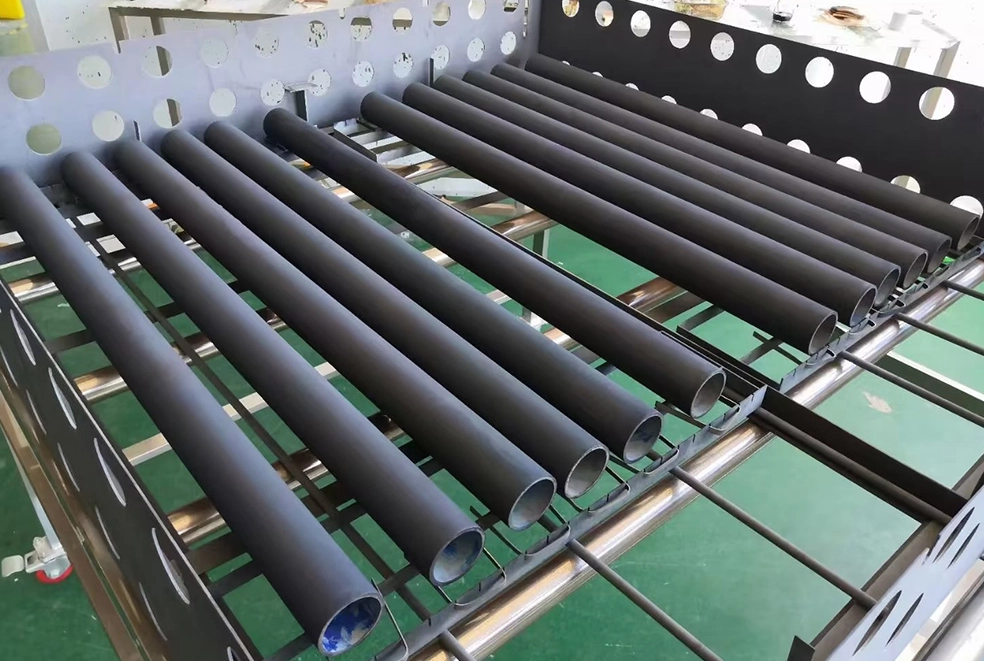

Seamless Titanium Tube

Welded Titanium Tubing

Gr5 Titanium Tube

Titanium Capillary Tube

Titanium Retangular/Square Tube

Titanium Coil Tube

Titanium Sputtering Target

Sintered Titanium Tube

Nitinol Tube

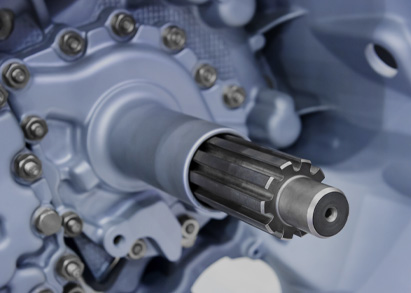

Titanium Rod

Titanium Block

Titanium Square/Hex Rod

Titanium Hollow Bar

Titanium Threaded Rod/Bar

Titanium Welding Wire

Titanium Wire

Titanium Clad Copper Rod

Nitiol Wire

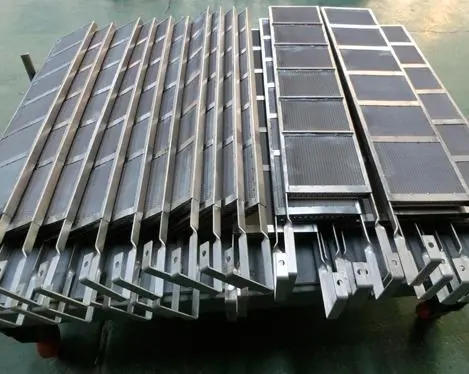

Ruthenium Coated Titanium Anodes

Iridium Coated Titanium Anode

Platinized Titanium Electrodes

PbO2 Titanium Anode

Titanium Basket

Titanium Cathode Plate

×

English

English