Titanium Strip Development

Titanium strip is difficult to be produced. In hot working, it is very easy to absorb impurities such as hydrogen, oxygen, carbon and nitrogen. At the same time, the wear resistance of titanium strip is poor, and the production process is complex. Before 2007, the industrial production of titanium strips in China was in a blank state, with titanium strips completely relying on imports, high procurement costs, long cycles, and unstable quality, seriously affecting the development of downstream application fields of titanium plates, strips, and welded pipes. In recent years, multiple domestic enterprises have successively rolled hot-rolled and cold-rolled titanium strips. Significant progress has been made in the production technology, heat treatment technology, and rolling process control technology of hot-rolled and cold-rolled pure titanium strips. With the development of domestic nuclear power, the demand for thin-walled titanium welded pipes, chemical and plate replacement titanium strips is becoming increasingly strong.

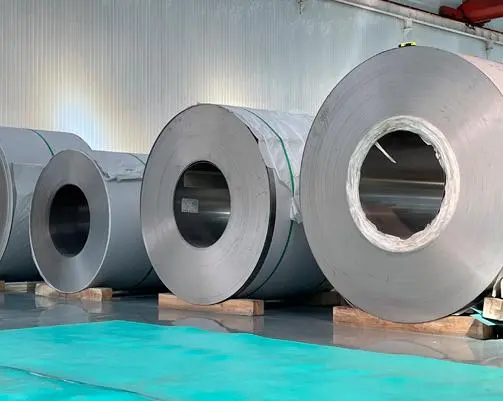

In 2020, the production of titanium and titanium alloy plates and strips in China accounted for 59.2% of the total titanium raw materials that year, with titanium strips accounting for more than half of the production. For applications in the field of nuclear power condensers and heat exchangers, using titanium strip has outstanding advantages such as high quality stability, suitability for batch continuous production, short production cycle, and cost reduction compared to using block single plates. Currently, titanium strip products have become the preferred material for welded pipes and plate heat exchangers used in nuclear power.

Titanium Strip Specifications

Cold rolled titanium strip thickness | 0.3-3mm |

Thickness of hot-rolled titanium strip | 3~4.75mm |

Executive standards | ASTM B265, ASTM F67, ASTM F136, AMS 4911 |

Material | gr1 gr2 gr5 gr23 |

Surface | Cold rolled bright surface and acid washed surface |

Titanium Strip Applications

Titanium strip has a low density (4.51KG/m³), a high melting point (1660 ℃), strong corrosion resistance, high specific strength, and good plasticity. There are many special uses for titanium strips, mainly in industries such as chemical, metallurgical, and electric power, titanium plates for plate heat exchangers, composite plates, welding pipes, automotive and motorcycle components, sports and leisure, medical components, steel and metallurgy, high-tech fields, and other industries. Titanium and titanium alloy strips can also be used to make automatic rifles, Mortar base plates, golf heads, etc. With the development of China's large aircraft projects and the vigorous development of coastal power plants, the usage of titanium strip coils will be increasing, especially for cold rolled titanium strip coils.

Advanced Capabilities in Titanium Strip Production

At CS Titanium, we pride ourselves on our ability to produce high-quality titanium strips, tailored to meet the specific needs of our clients. Our titanium strip coils can be produced as commercially pure or alloyed, depending on your application requirements. Our knowledgeable staff is always ready to assist you in determining the best choice for your needs.

Our titanium strips for soldering are renowned for their superior quality and performance. They offer excellent solderability, making them ideal for various applications in industries such as electronics, aerospace, and automotive.

Our standard rolling capability for titanium strips is 5%; however, we can achieve a rolling tolerance of approximately 2% for more precise requirements. This flexibility in our production process ensures we can meet the diverse needs of our clients.

We also have a range of titanium strips for sale, available in various sizes and grades. Whether you need titanium soldering strips for a specific project or a bulk order of titanium strip coils, CS Titanium is your reliable partner for all your titanium strip needs.

Achieving the Ideal Surface Finish for Titanium Strips

At CS Titanium, we prioritize achieving the ideal surface finish for your titanium strip. We understand the importance of maintaining precise temperature control throughout the production process. This control ensures uniform mechanical properties and grain structure across the entire length of the coil, which is crucial for the final product’s quality.

If the grains grow too large, it can lead to inconsistent mechanical properties and an undesirable surface finish. To prevent this, we employ a sealed furnace with a protective interior atmosphere filled with a shielding gas. This environment is crucial for producing best-in-class titanium strips.

The protective atmosphere in the furnace prevents the formation of excess oxide, allowing the titanium strip to retain its rolled finish. This process aids in surface control, ensuring the titanium strip’s surface finish meets your exact specifications.

Our team of experienced metallurgists is dedicated to working closely with you to achieve your desired final properties. We leverage our expertise and advanced production techniques to deliver titanium strips that meet your specific requirements and exceed your expectations.

Features and Applications of the Titanium Soldering Strips

At CS Titanium, we offer high-quality titanium soldering strips that provide several advantages over traditional steel clamps. Our titanium strips for soldering are resistant to solder and enamel adhesion, maintain their strength even when red hot, and do not erode or flake away under heat. This allows for smaller clamp tips and less interference with nearby joints due to titanium’s lower heat transfer rate compared to steel clamps.

Our titanium soldering strips are sold in packs of 10 as straight 4" annealed "blanks". This allows you to bend and shape them into your ideal clamp designs, catering to the unique needs of each soldering situation. Every jeweler has their unique soldering style, and our titanium soldering strips can be easily customized to suit these individual needs.

These versatile titanium soldering strips have found several applications, including holding ear wires during soldering, clamping bails and jump rings, re-setting warped sweat-soldered panels, clamping several items together during soldering, soldering hemispheres into a full sphere, and holding spheres onto ring shanks.

We are committed to providing high-quality, versatile titanium products that cater to the unique needs of our clients. Contact us today to learn more about our titanium soldering strips and their applications.

CS Titanium Hot Titanium Plate & Sheet Types are Recommended

English

English